© MOCO Shredder

up to 3 m³ / hMOCO AZ 7F

up to 4 m³ / hMOCO AZ 9F

up to 5 m³ / hMOCO AZ 11

up to 6 m³ / hMOCO AZ 14E

up to 15 m³ / hMOCO AZ 15E

up to 15 m³ / hMOCO AZ 20

up to 30 m³ / h

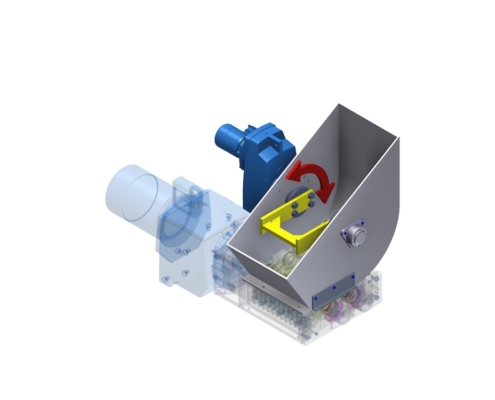

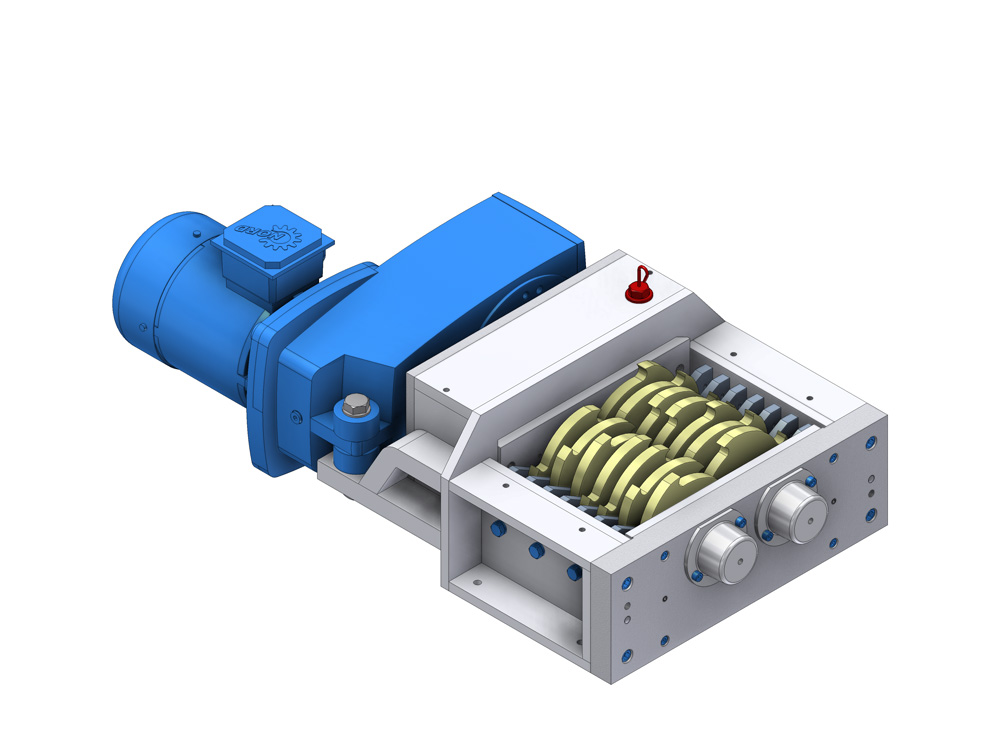

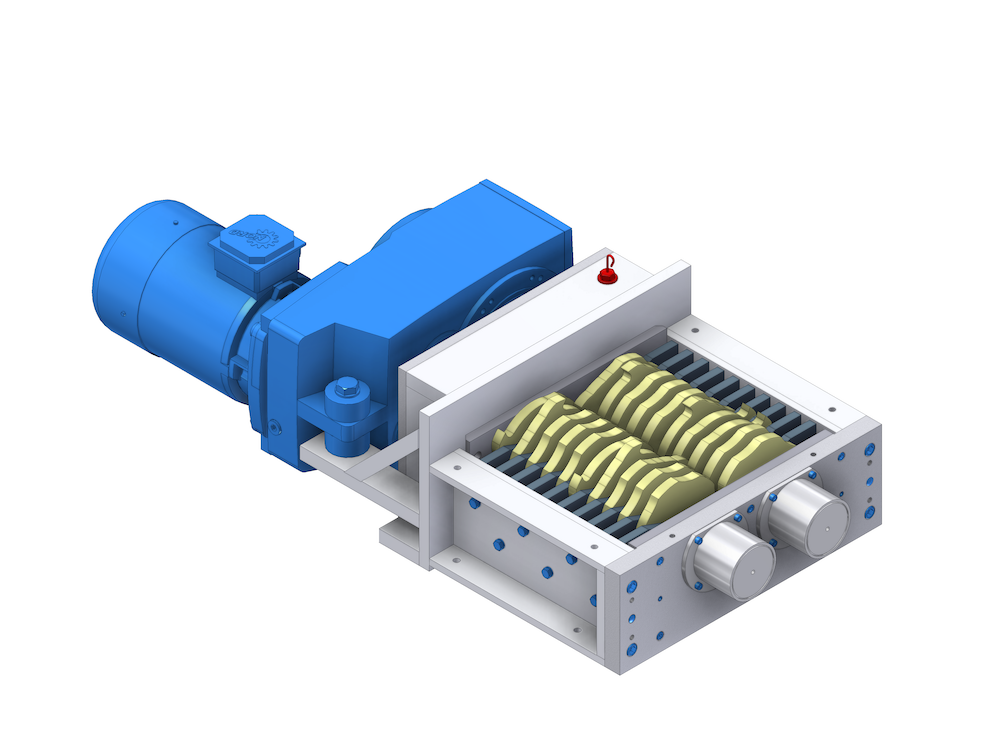

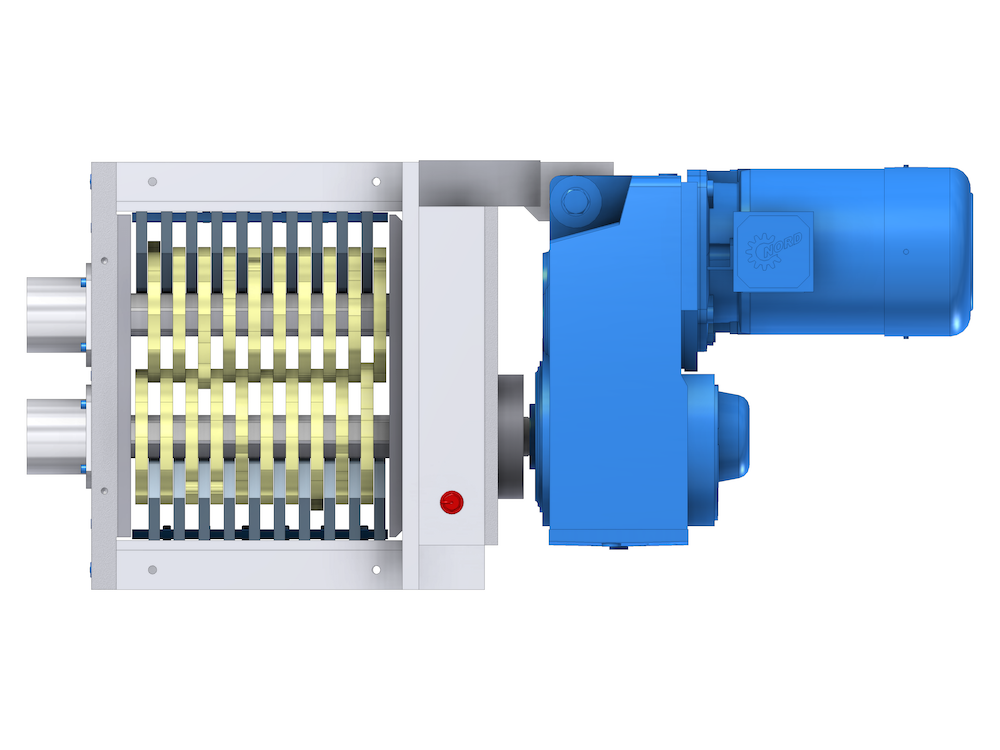

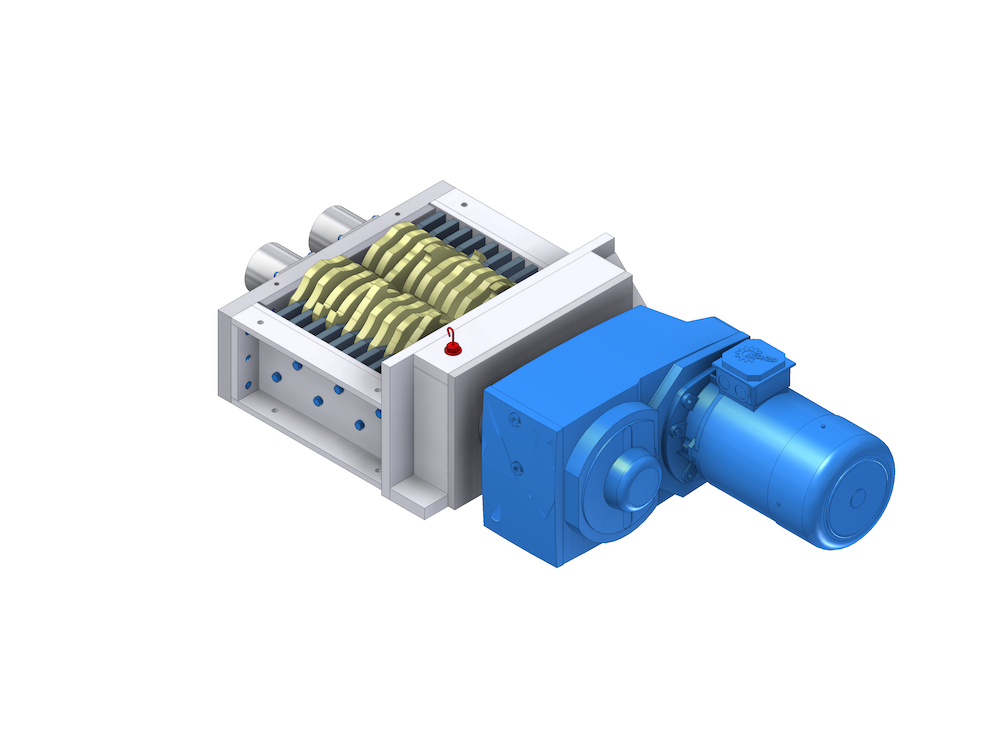

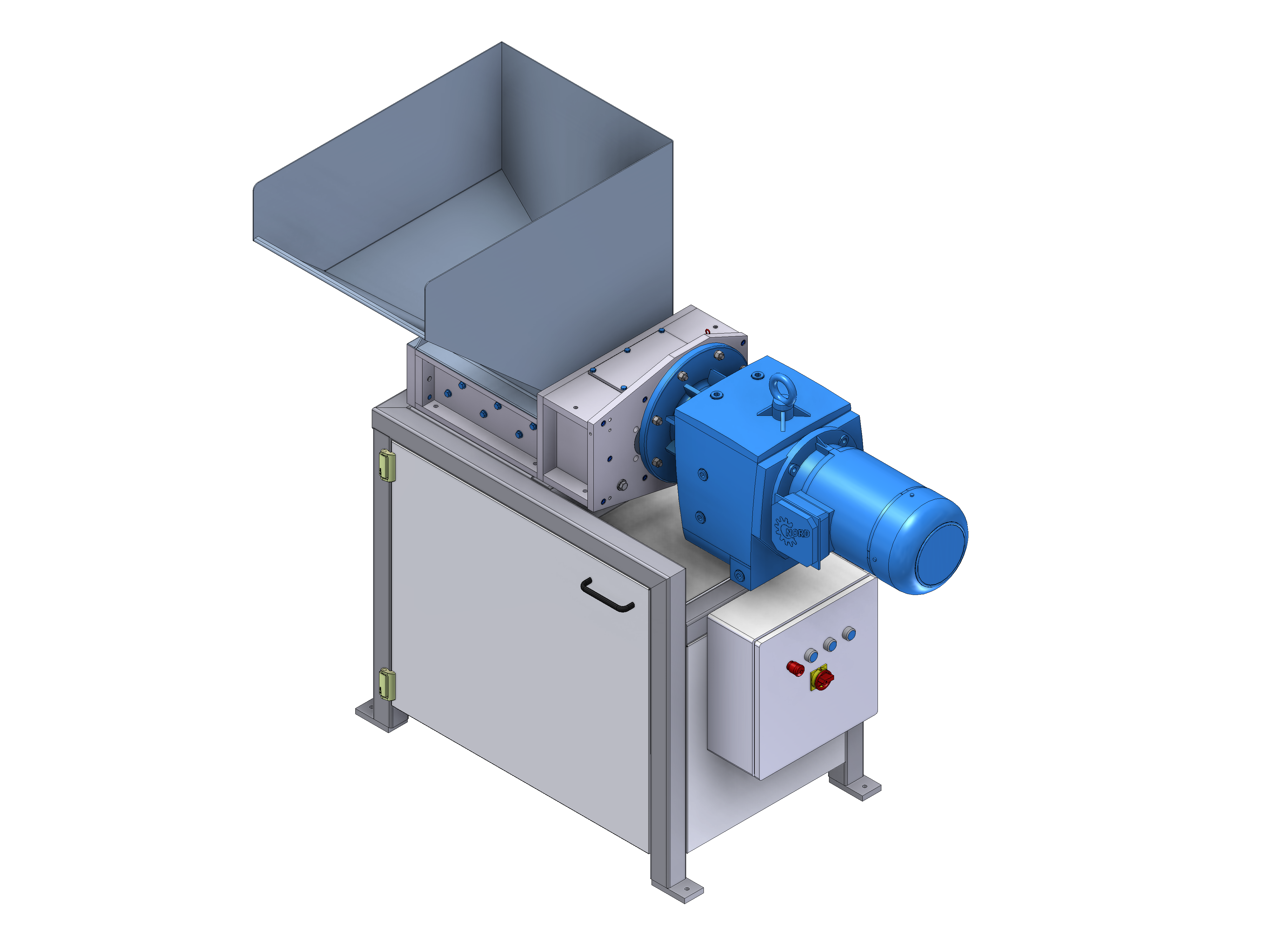

Technical data MOCO AZ 5F

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 1 to 2 cubic meters per hour

THE DIMENSIONS

- Cutting section: 258 x 358 mm

- Exterior dimensions: 999 x 521 x 255 mm

- Weight: approx 270 kg

- Drive power: 3 bis 5.5 kW

- Voltage: 400 V / 50 Hz

THE OPTIONS

- Customized hopper and frame

- Cutting thicknesses of 9, 12 und 15,5 mm, respectively upon request

- Feeding devices

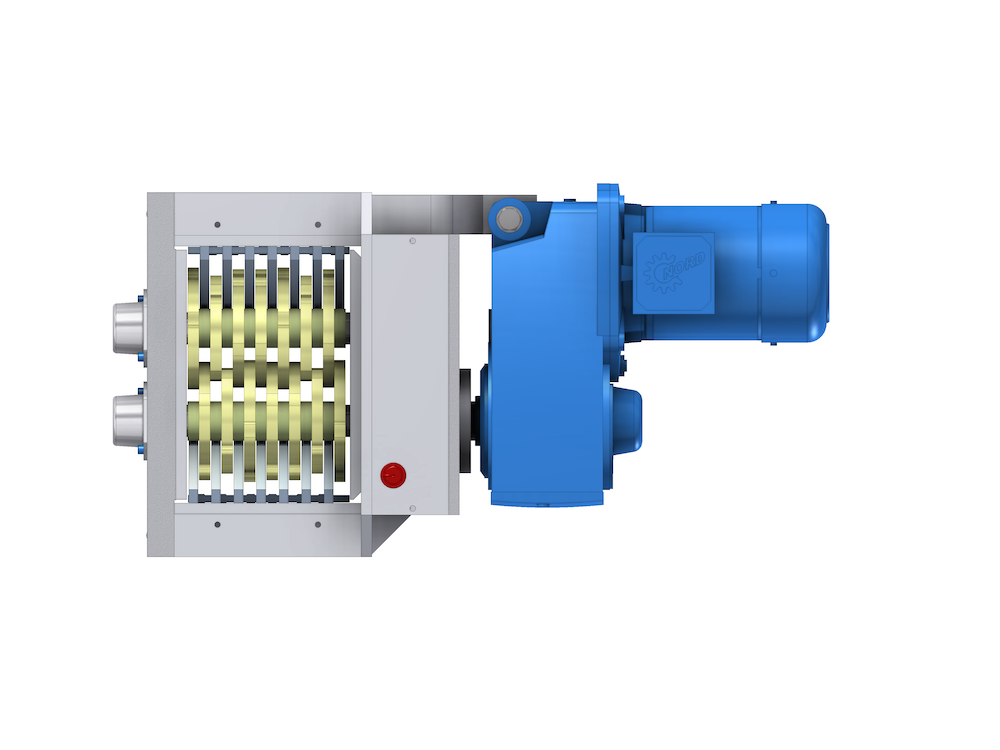

Technical data MOCO AZ 7F

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 2 to 4 cubic meters per hour

THE DIMENSIONS

- Cutting section: 358 x 430 mm

- Exterior dimensions: 1,297 x 574 x 306 mm

- Weight: approx 400 kg

- Drive power: 5.5 to 7.5 kW

- Voltage: 400 V / 50 Hz

THE OPTIONS

- Customized hopper and frame (e.g. for 240 litres containers)

- Cutting thicknesses of 5, 9, 12 and 15.5 mm, respectively upon request

- Feeding devices (MOCO ZB 01)

- Sieves to obtain a specific final particle size

- Connecting funnel for extraction units

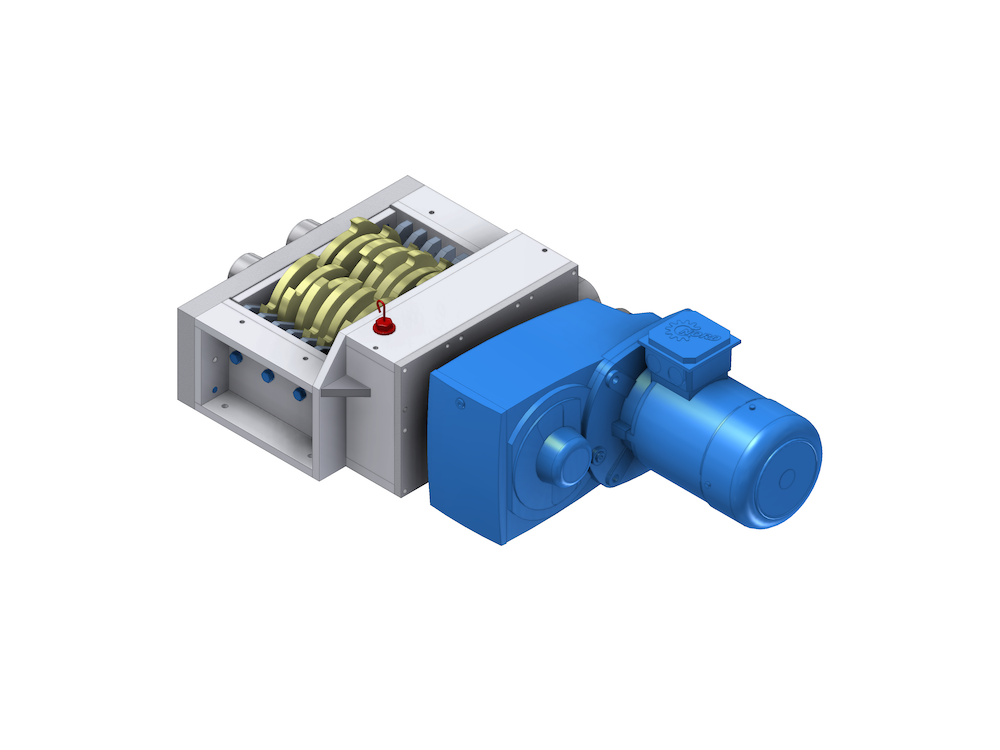

Technical data MOCO AZ 9F

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 3 to 5 cubic meters per hour

THE DIMENSIONS

- Cutting section: 433 x 500 mm

- Exterior dimensions: 1,436 x 650 x 350 mm

- Weight: approx 670 kg

- Drive power: 7.5 kW

- Voltage: 400 V / 50 Hz

THE OPTIONS

- Customized hopper and frame

- Cutting thicknesses of 12, 15 and 19 mm, respectively upon request

- Feeding devices (MOCO ZB 01)

- Connecting funnel for extraction units

- Sieves to obtain a specific final particle size

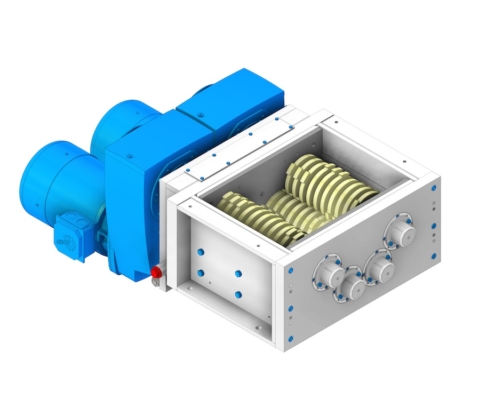

Technical data MOCO AZ 11

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 3 to 6 cubic meters per hour

THE DIMENSIONS

- Cutting section: 509 x 500 mm

- Exterior dimensions: 1,903 x 650 x 550 mm

- Weight: approx 950 kg

- Drive power: 7.5 to 22 kW

- Voltage: 400 V / 50 Hz

- Further cutting unit dimensions available

THE OPTIONS

- Customized hopper and frame

- Cutting thicknesses of 12, 15.5 and 19 mm, respectively upon request

- Feeding devices (MOCO ZB 01)

- Sieves to obtain a specific final particle size

- Connecting funnel for extraction units

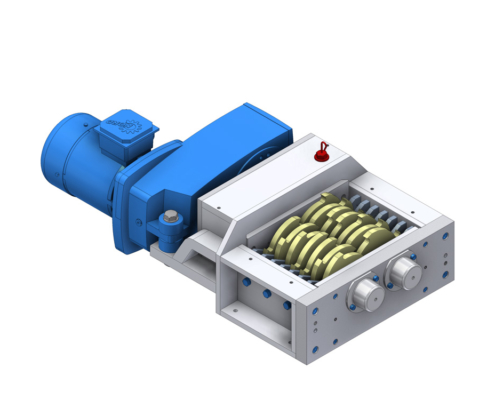

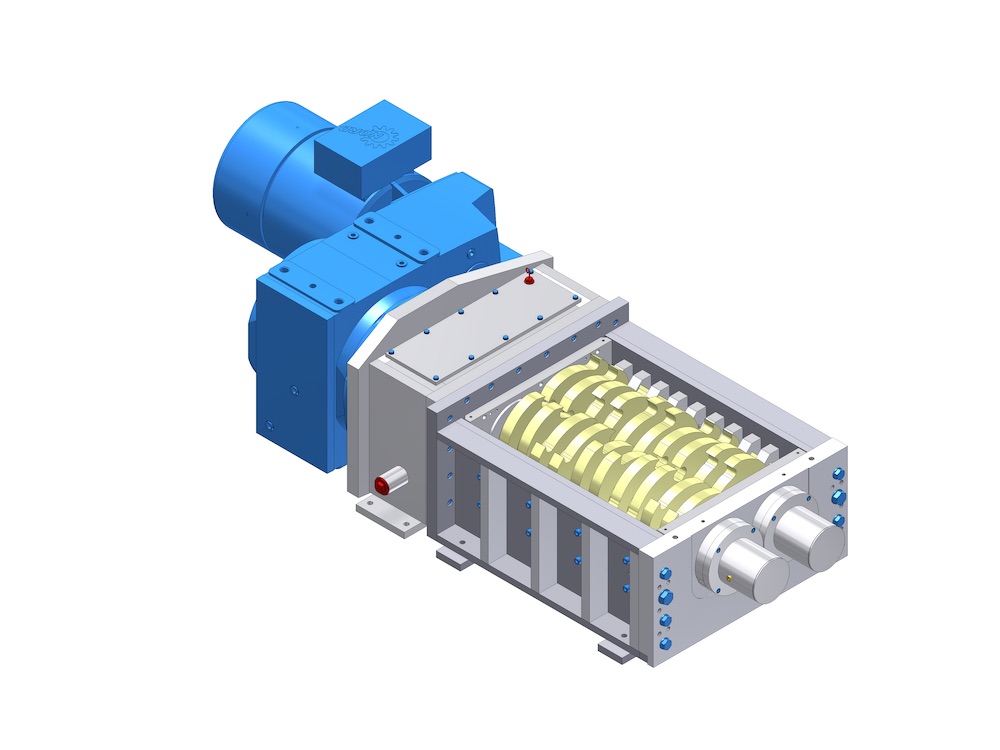

Technical data MOCO AZ 14E

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 8 to 15 cubic meters per hour

THE DIMENSIONS

- Cutting section: 650 x 600 mm

- Exterior dimensions: 2,206 x 790 x 650 mm

- Weight: ca. 1,750 kg

- Drive power: 15 to 37 kW

- Voltage: 400 V / 50 Hz

THE OPTIONS

- Customized hopper and frame

- Cutting thicknesses of 19, 25 and 31 mm, respectively upon request

- Feeding devices (MOCO ZB 01)

- Connecting funnel for extraction units

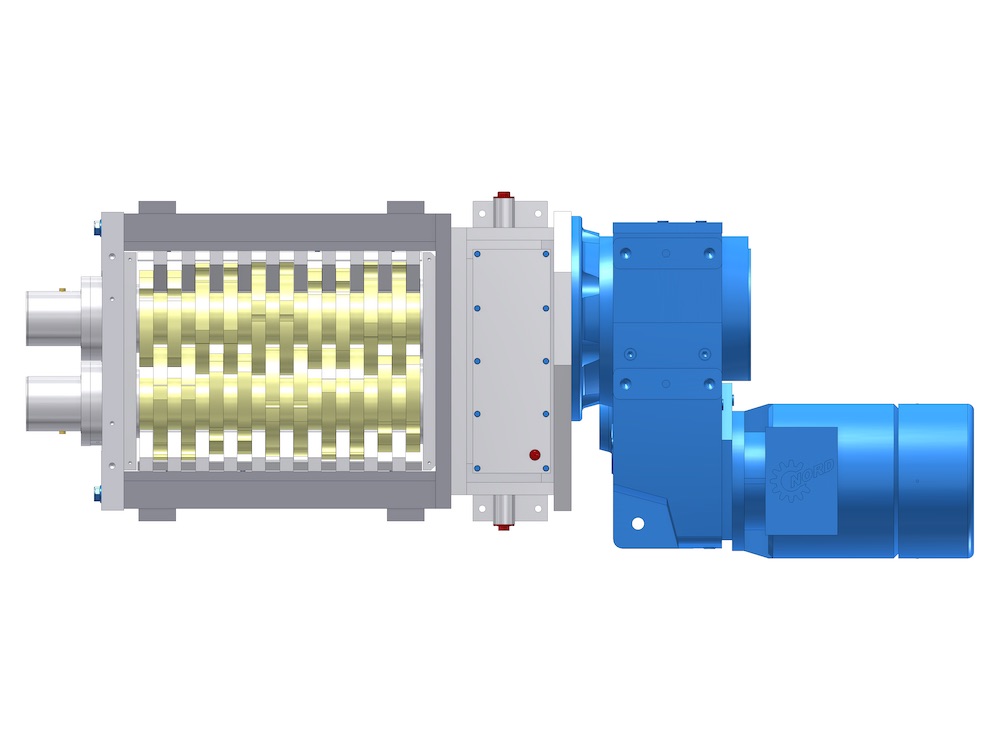

Technical data MOCO AZ 15E

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 10 to 15 cubic meters per hour

THE DIMENSIONS

- Cutting section: 932 x 600 mm

- Exterior dimensions: 2,486 x 790 x 650 mm

- Weight: approx 2,320 kg

- Drive power: 15 up to 37 kW

- Voltage: 400 V / 50 Hz

- Further cutting unit dimensions available

THE OPTIONS

- Customized hopper and frame

- Cutting thicknesses of 19, 25 and 31 mm, respectively upon request

- Feeding devices (MOCO ZB 01)

- Sieves to obtain a specific final particle size

- Connecting funnel for extraction units

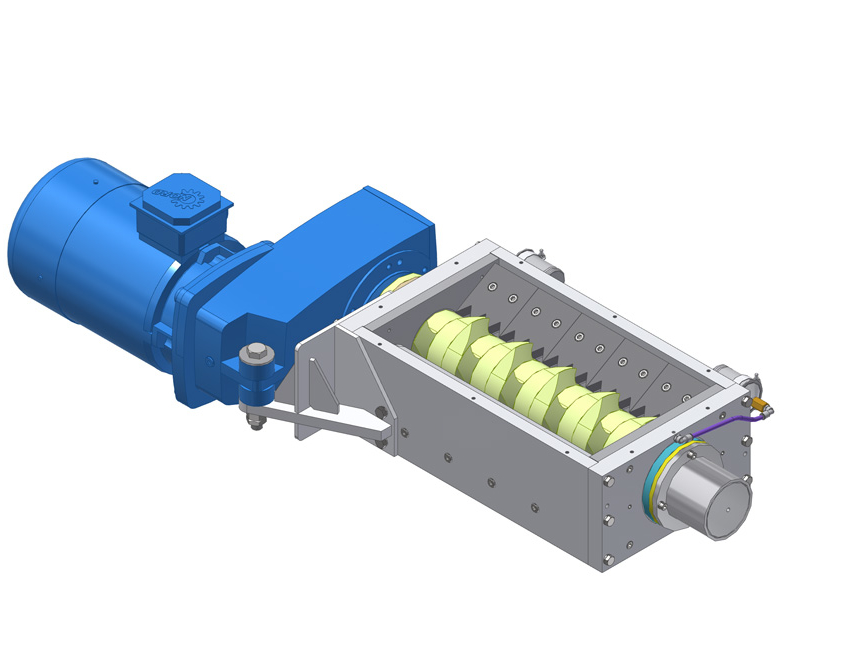

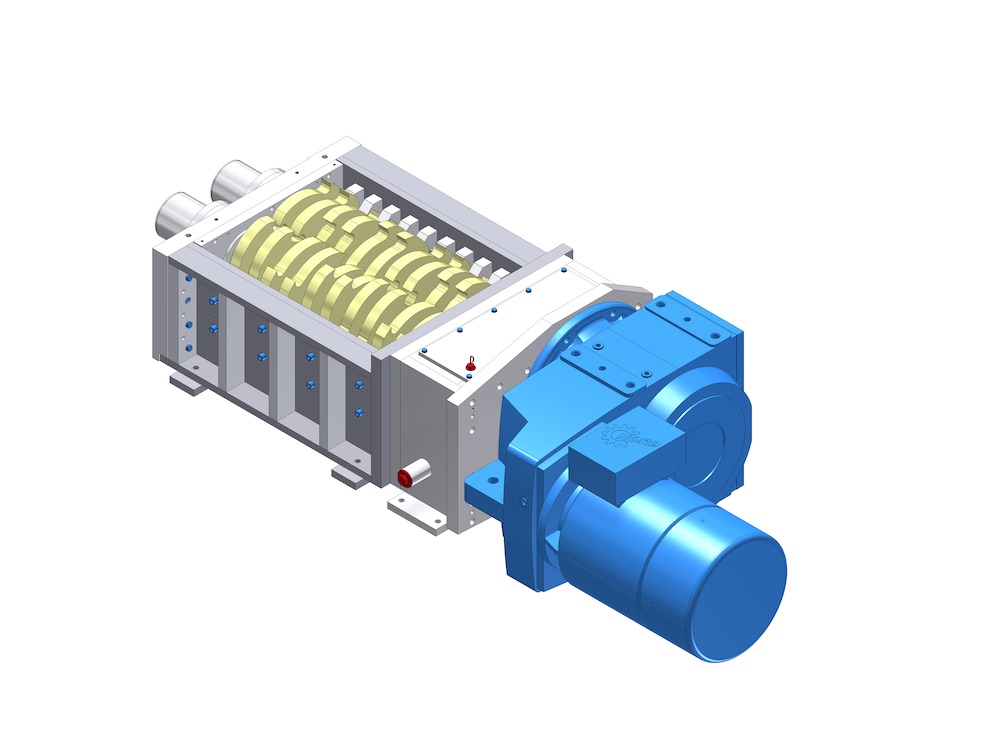

Technical data MOCO AZ 20

Throughput performance with standard cutting discs,

reference material of loose mixed waste approx 18 to 30 cubic meters per hour

THE DIMENSIONS

- Cutting section: 1,003 x 710 mm

- Exterior dimensions: 2,890 x 1,118 x 750 mm

- Weight: ca. 4,000 kg

- Drive power: 30, 45 and 55 kW

- Voltage: 400 V / 50 Hz

THE OPTIONS

- Customized hopper and frame

- Cutting thicknesses of 35 and 45 mm, respectively upon request

- Feeding devices (MOCO ZB 01)

- Connecting funnel for extraction units

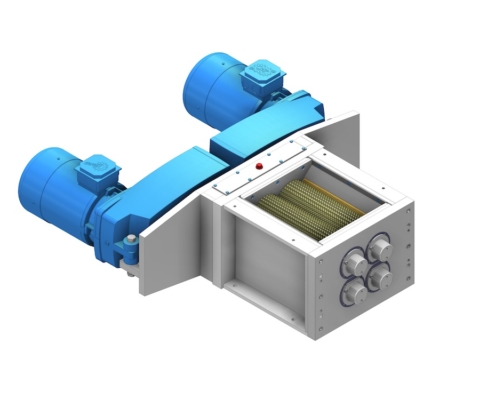

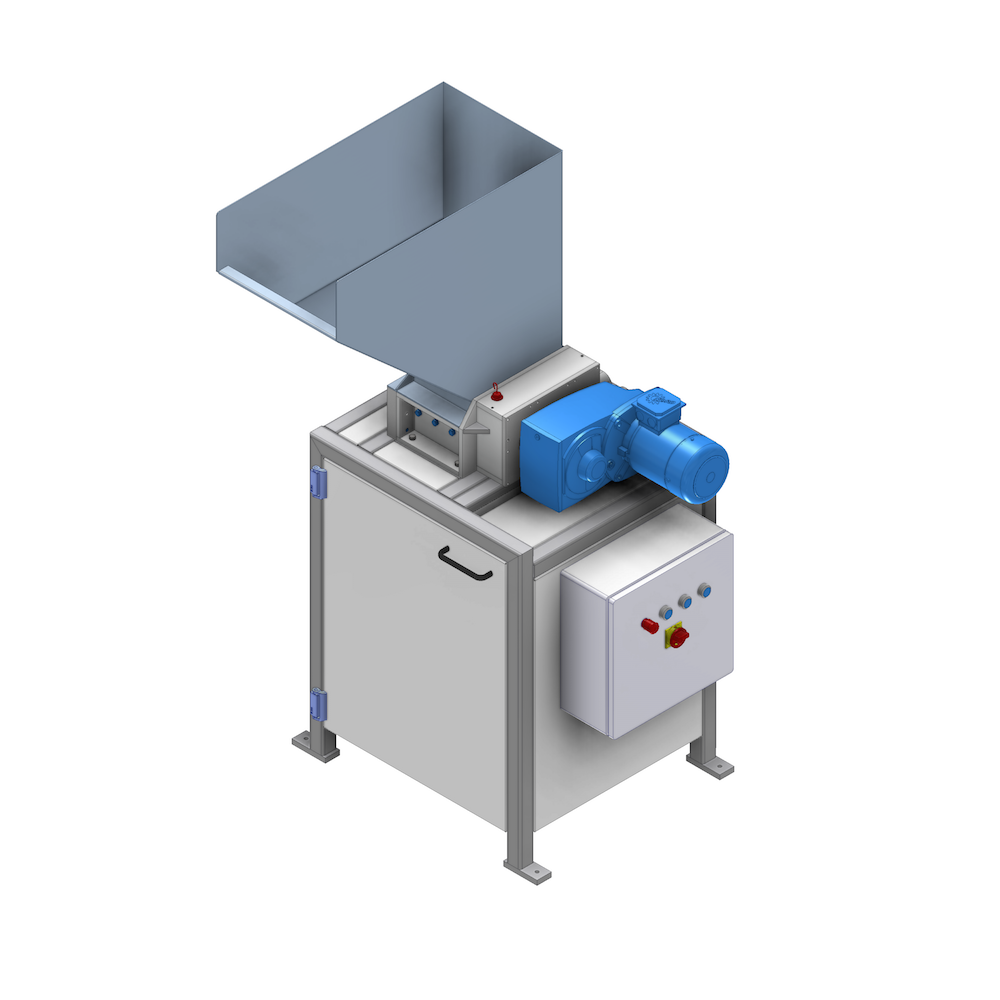

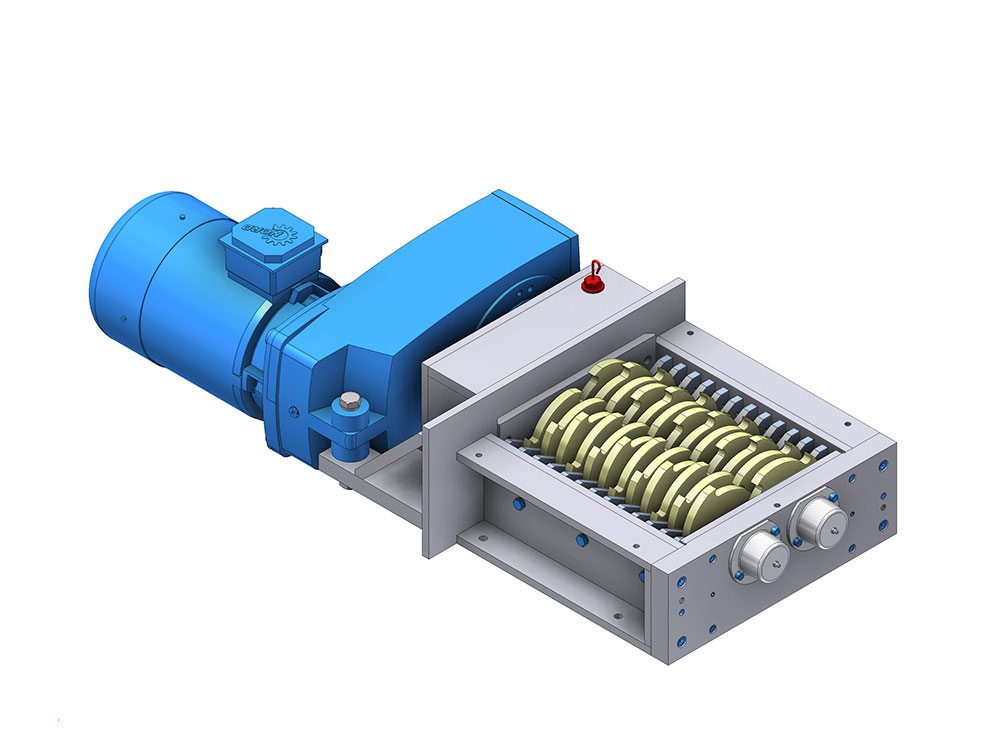

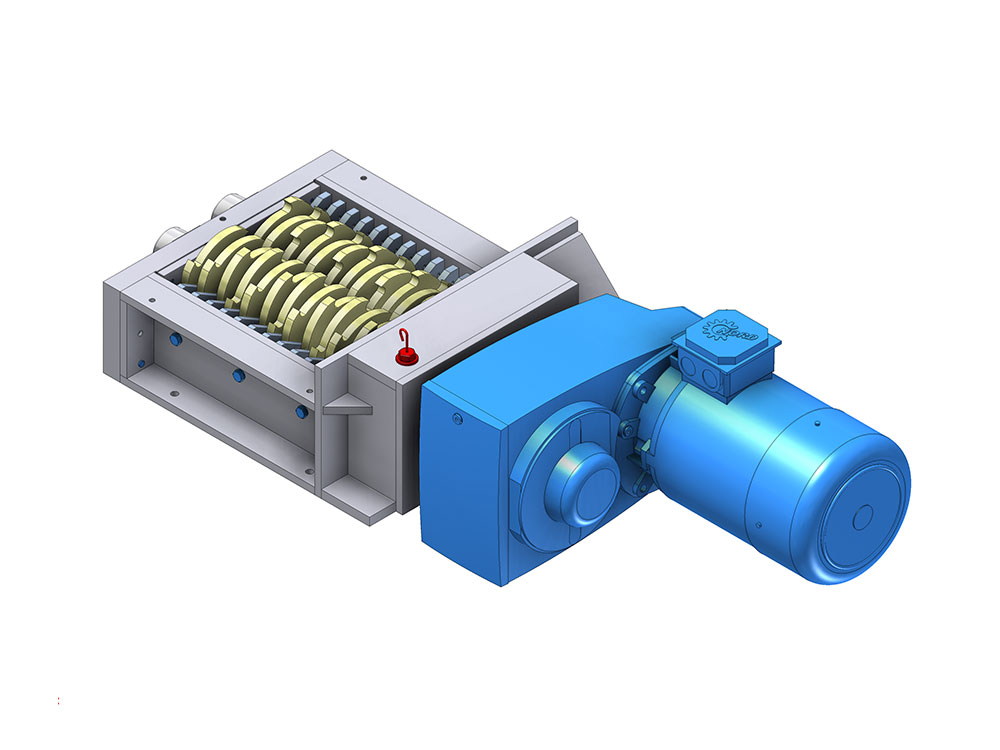

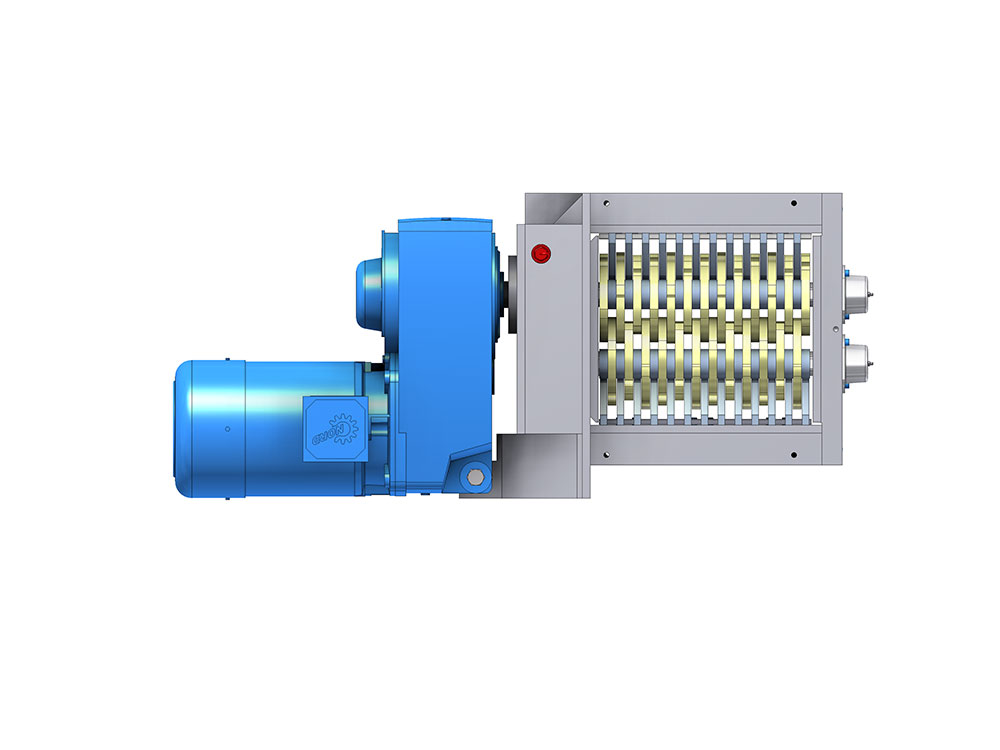

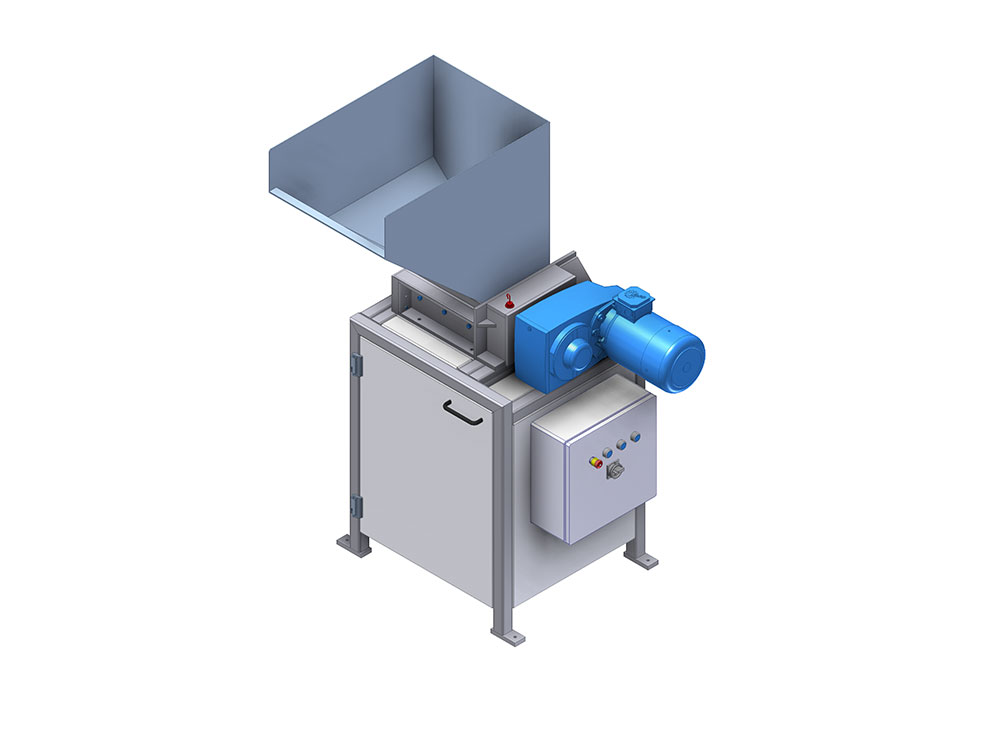

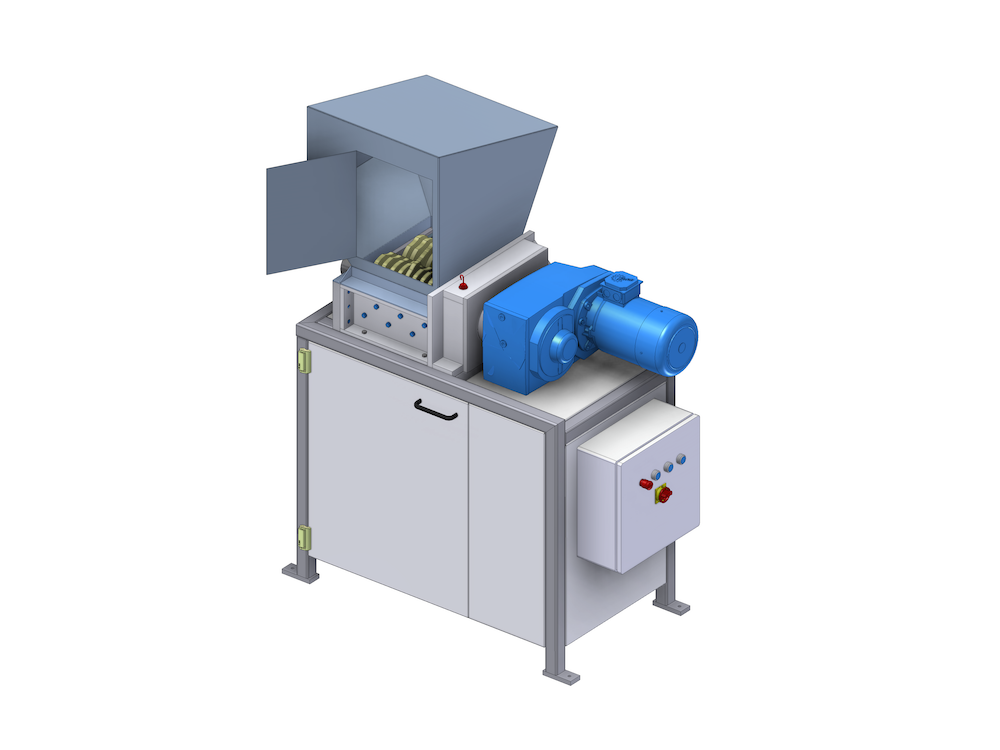

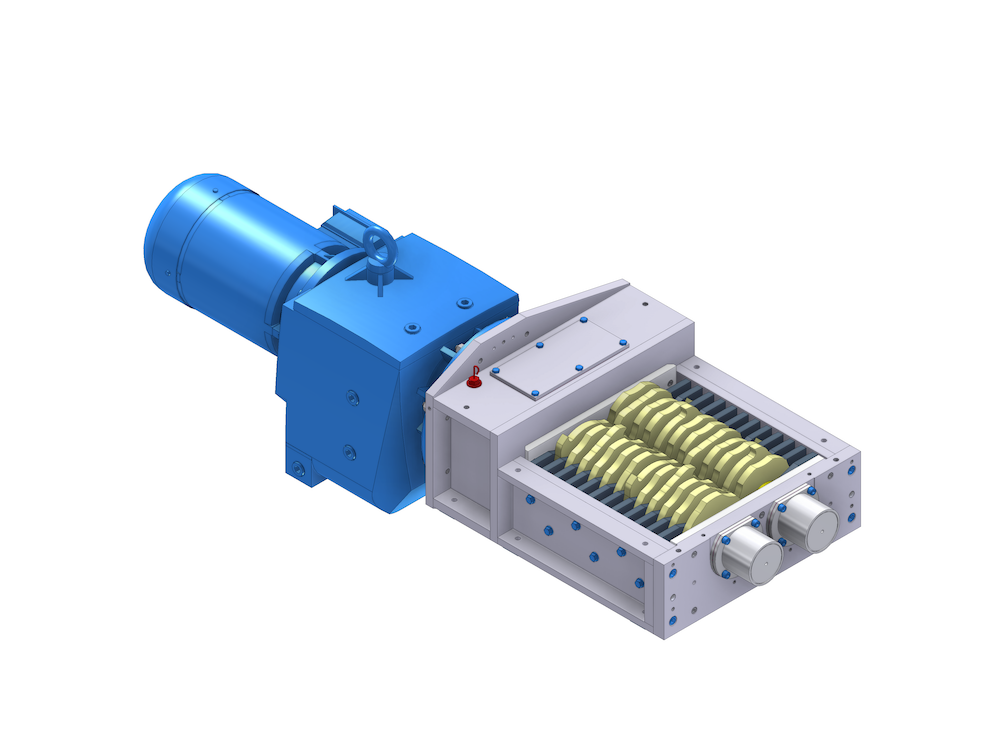

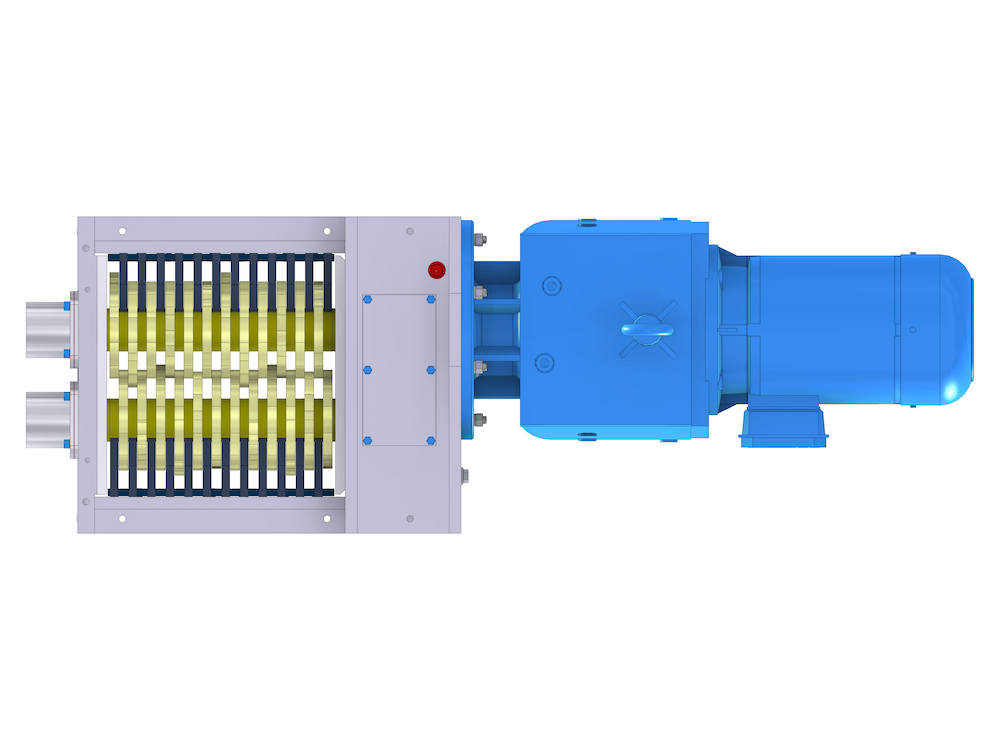

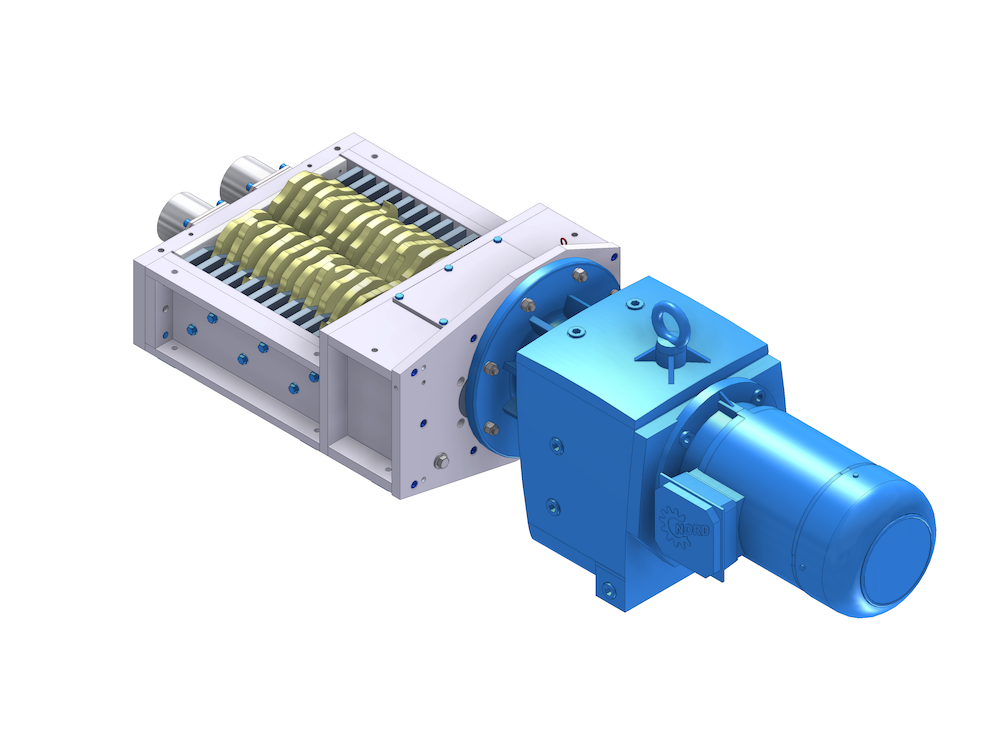

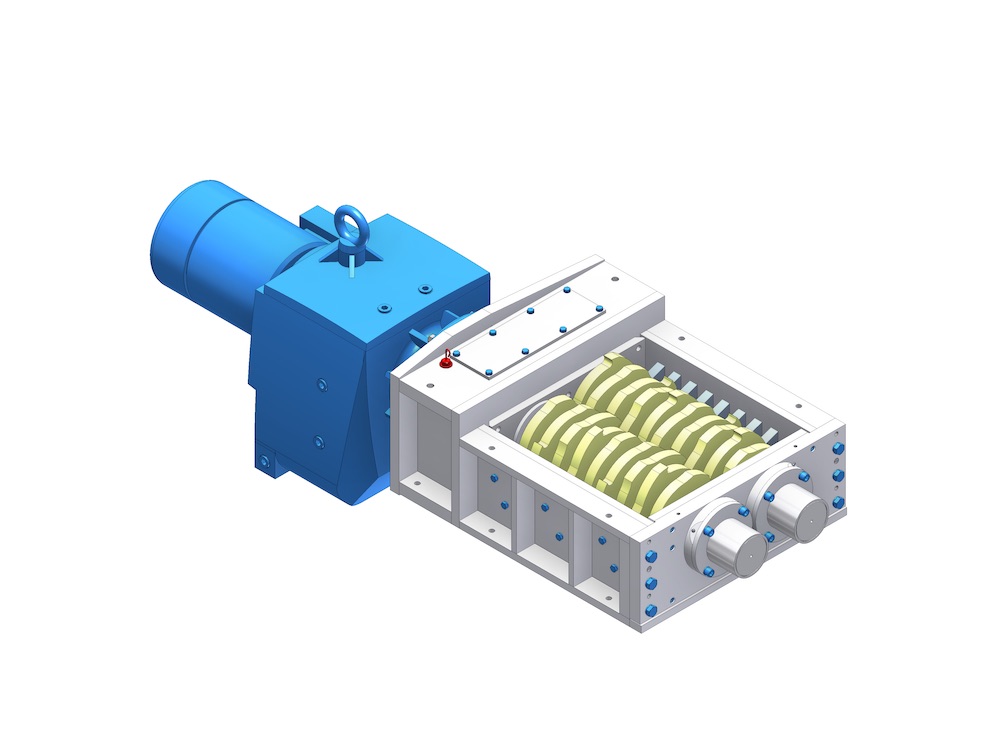

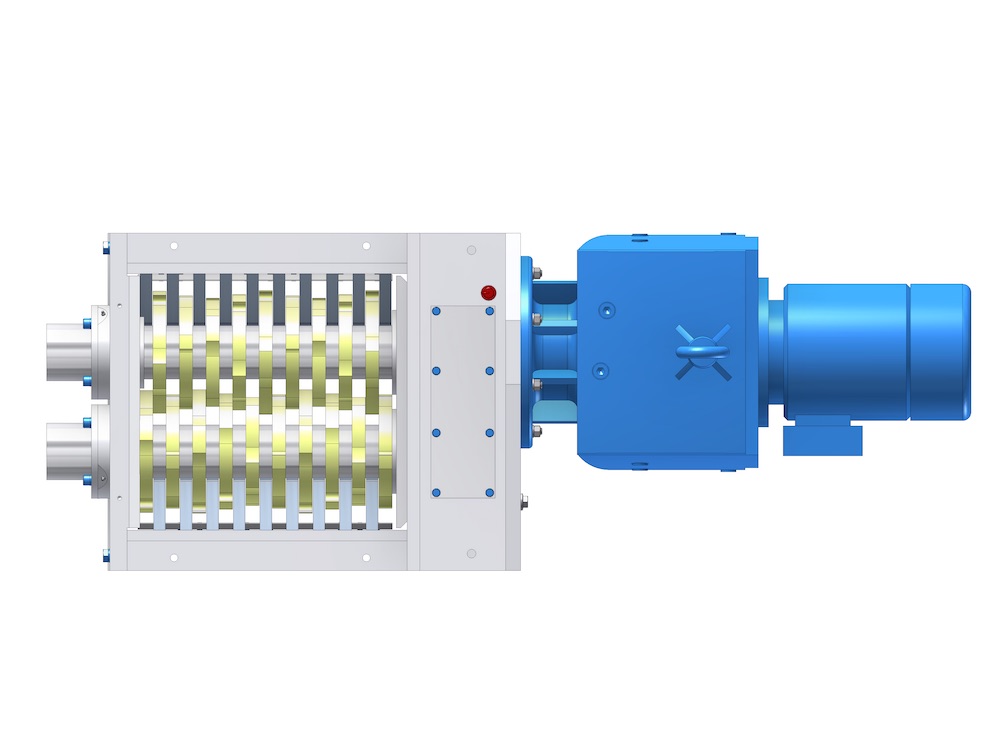

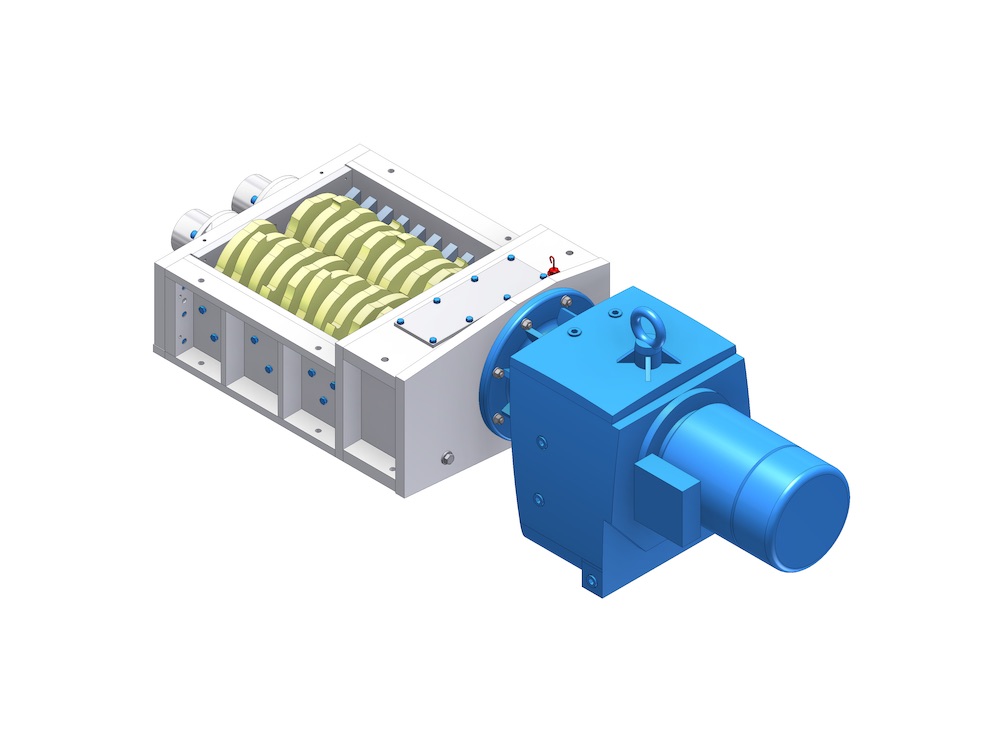

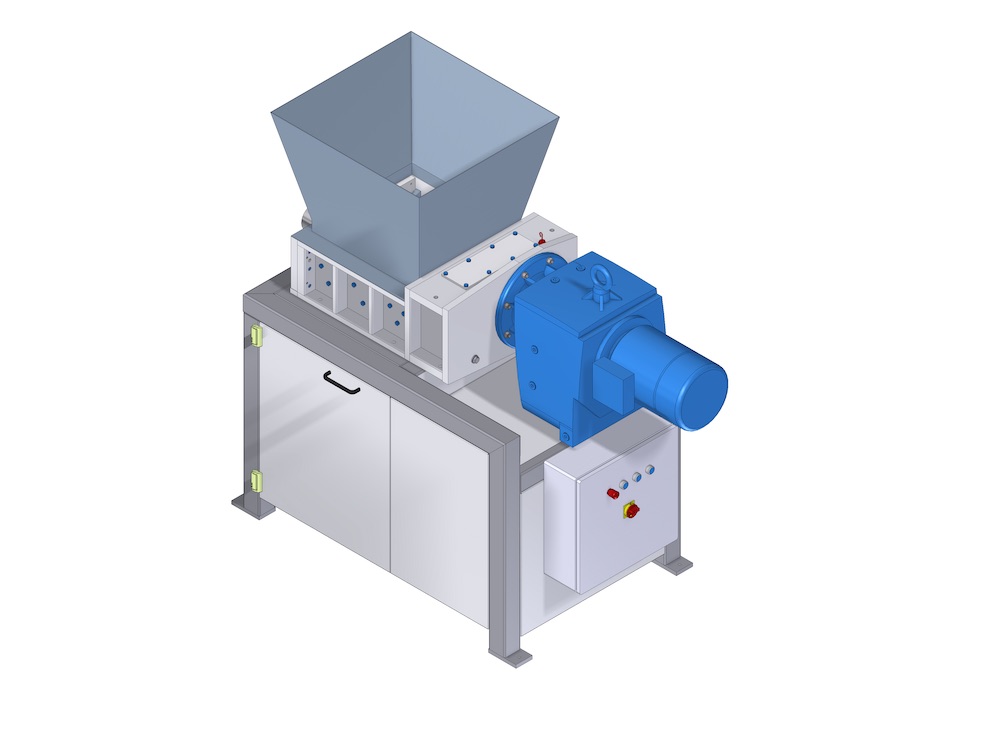

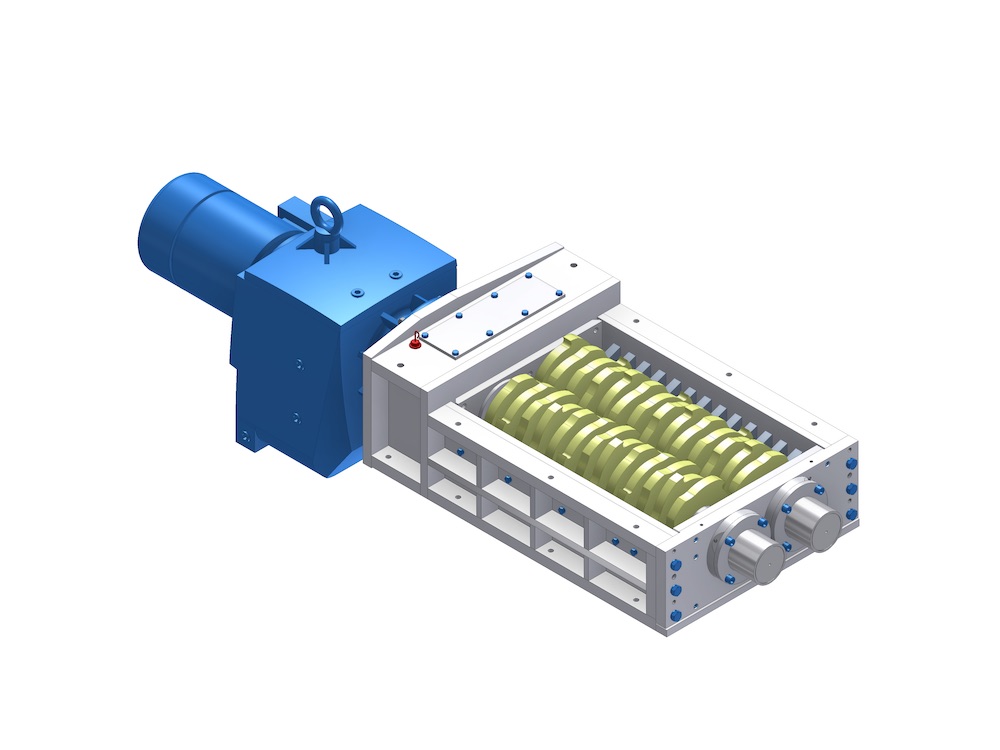

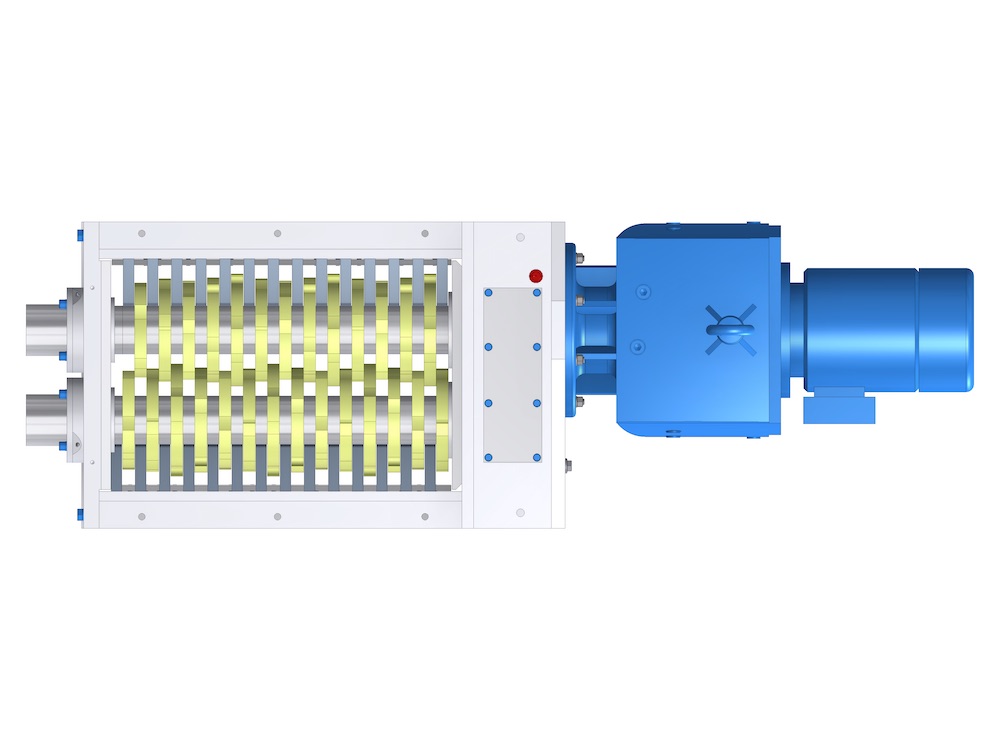

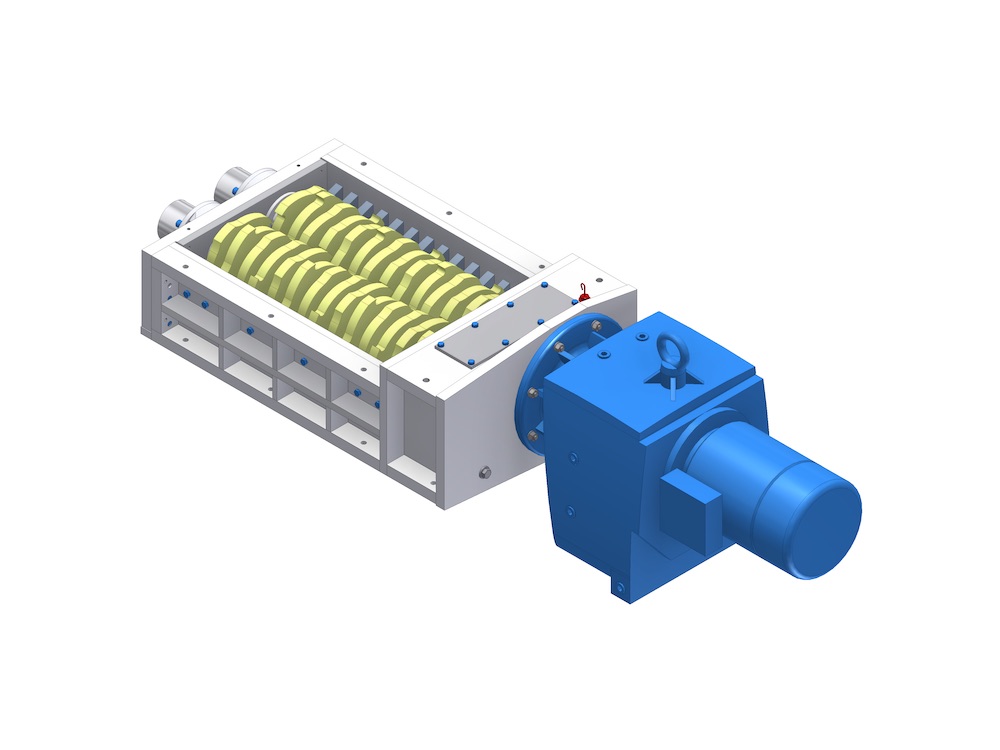

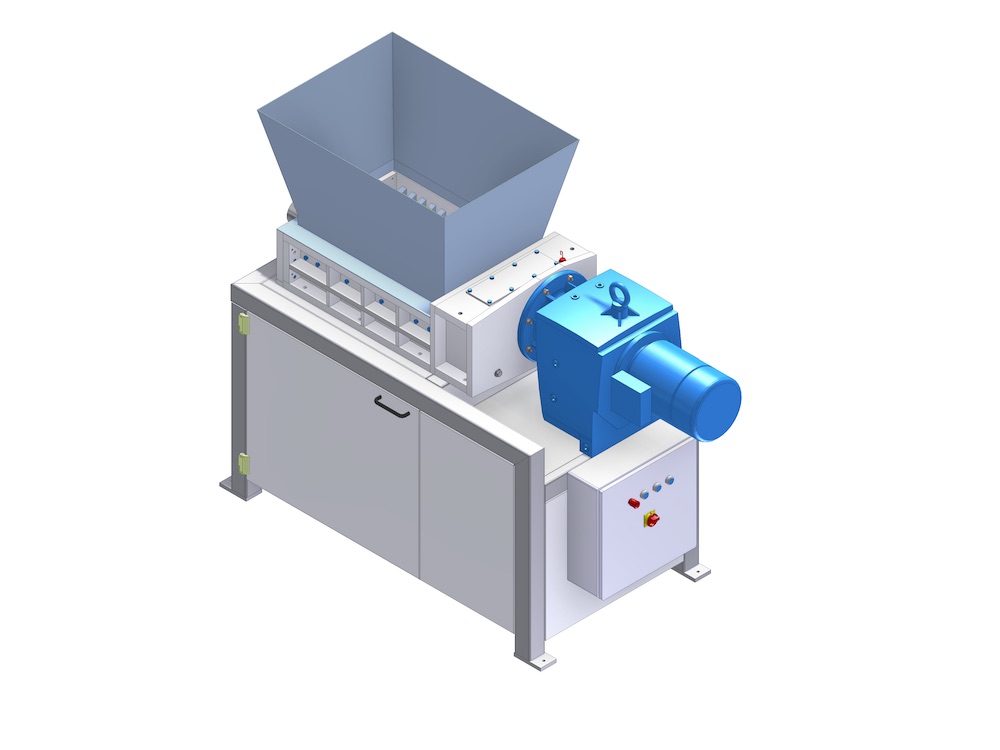

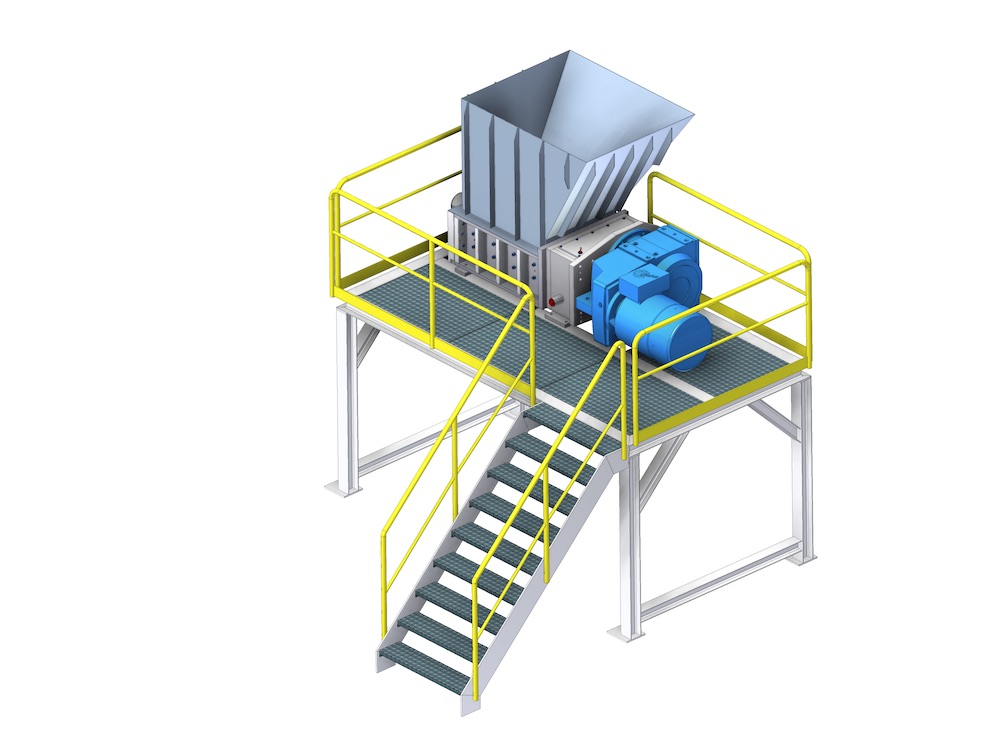

Innovative shredding machines from experts

MOCO Shredder stands for highest quality and individual design.

In short: Everyone at MOCO is an expert. Each shredding task is different; therefore, no machine is built here like the other.

Individual workshop production enables us to design each system perfectly according to customer specifications. The actual machine type is only the basis. After that we will adapt the base machine. This includes fitting the cutter set best suited for the given material, ensuring suitable motor output and correct gear ratio, designing the electrical control system and the feeder as well as determining the hopper volume. The result is a robust shredding machine in a customised design that provides sufficient safety reserves and has abundant power even in the toughest continuous use.

The two-shaft shredders, too, impress with their modern appearance, consistently high material quality and a high shredding frequency. For you, this means long-term investment security.

Did you know?

MOCO also offers shredders as integrated systems, plug-and-play units and turnkey systems to make your day-to-day work as easy as possible.