MOCO stands for experience and technical knowledge. As a company operating globally, we have been advising numerous customers on all continents for many years.

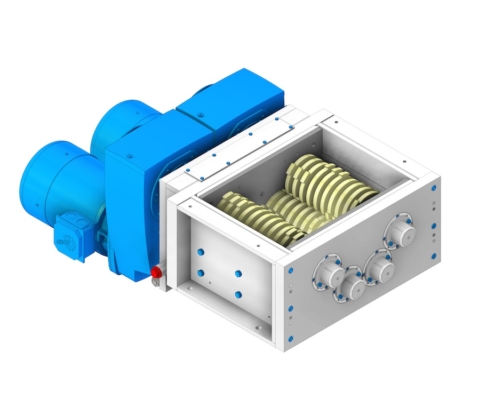

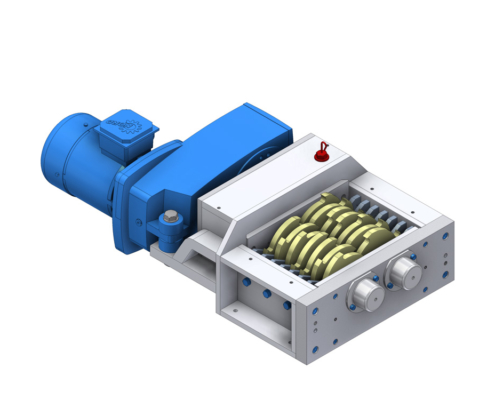

Flexibility, care and innovation. These terms characterise MOCO from Viernheim, Germany. As a company rich in tradition combining proven technology with innovative concepts, many customers rely on our expertise. Because it is possible to shred almost any solid material. MOCO has decades of experience in this field. And precisely this experience teaches us that no two materials react alike. Wood, plastics, paper, glass, metals, rubber, natural products, minerals, chemicals or other substances: Each material in its specific initial form and quantity reacts differently during shredding depending on the degree of shredding and the physical and chemical properties.

Reliable and durable shredding technology therefore requires planning, technical knowledge and experience. Only customised technology will secure the desired result. In many cases, this includes shredding of non-uniform materials. Mixed sizes and big differences in the initial form additionally increase the demands on the shredding technology.

Shredding technology from MOCO in Viernheim – tailored perfectly to your needs.

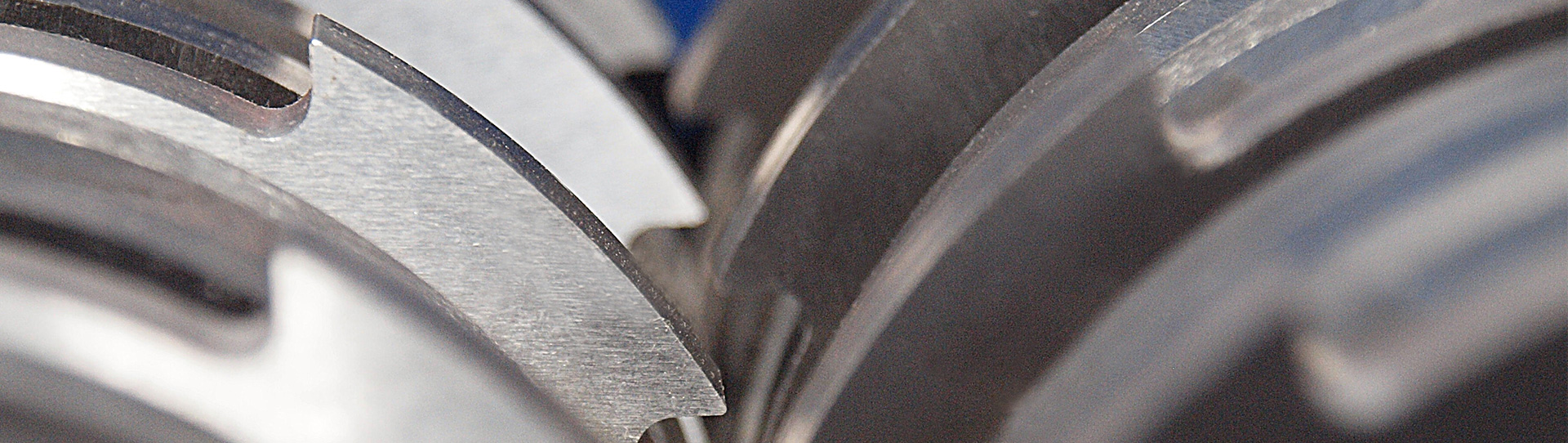

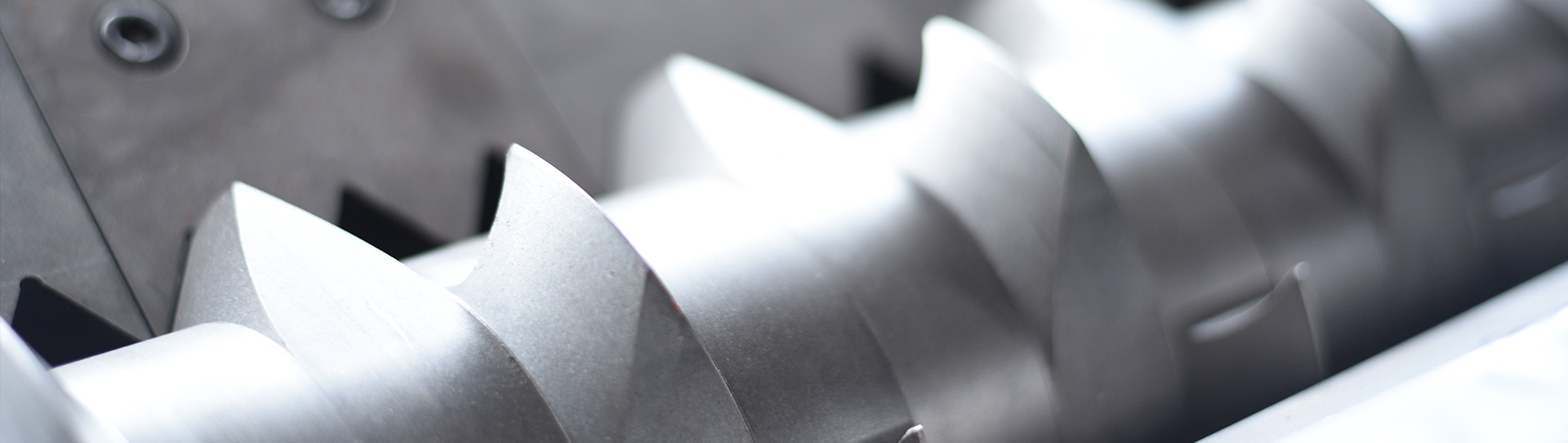

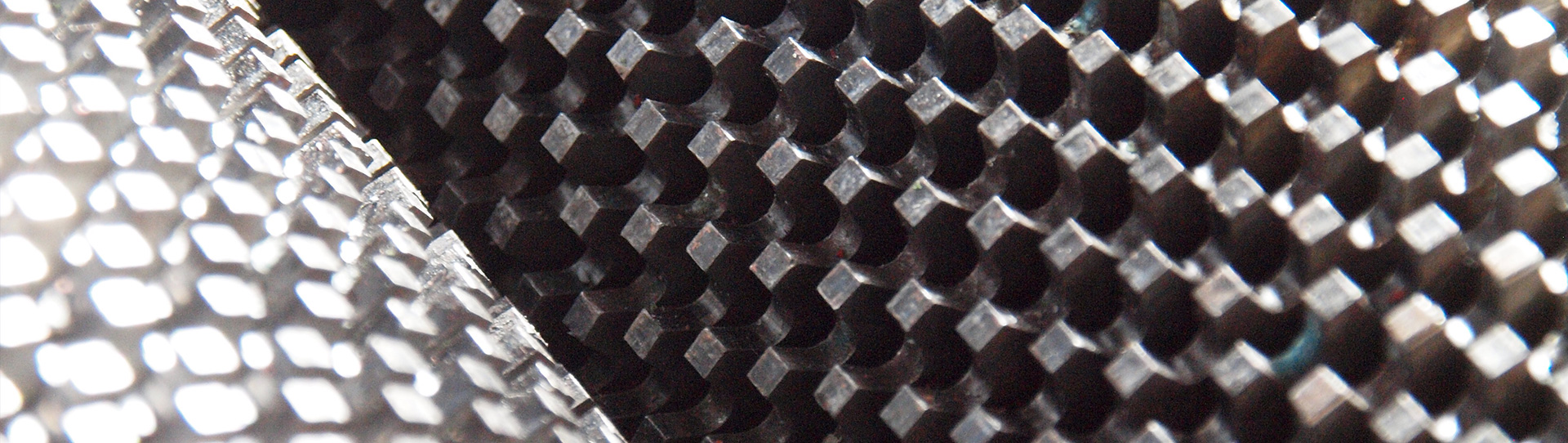

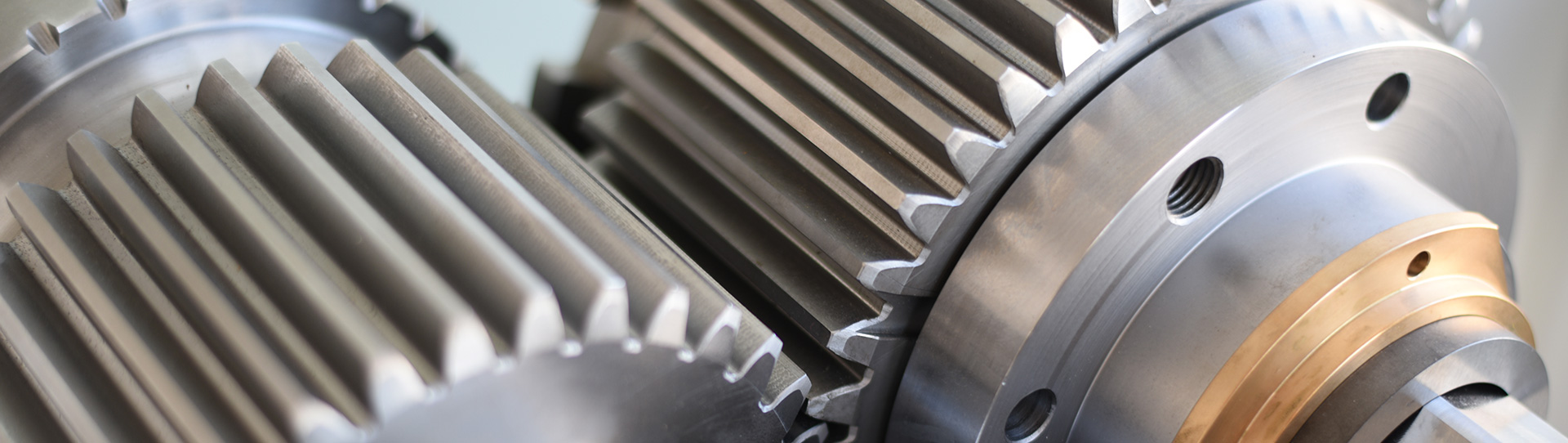

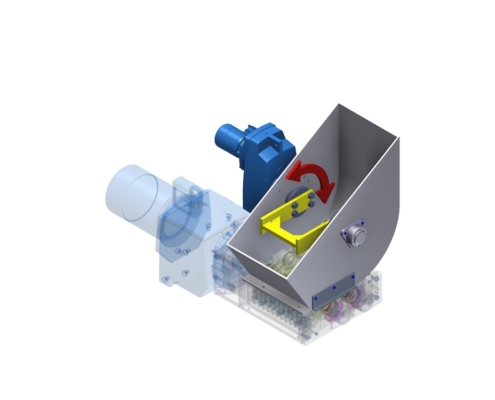

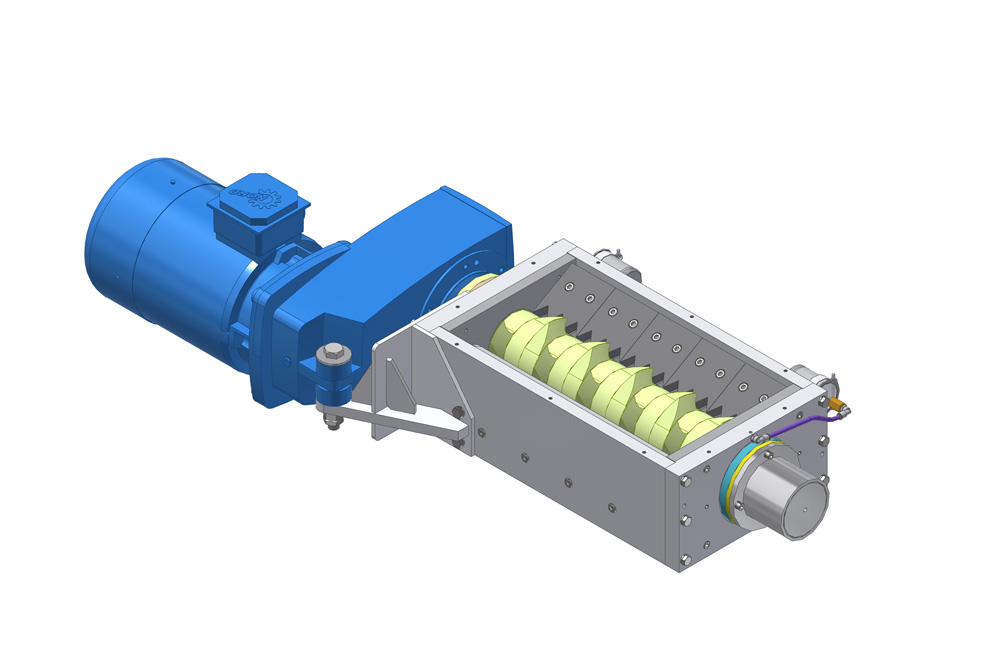

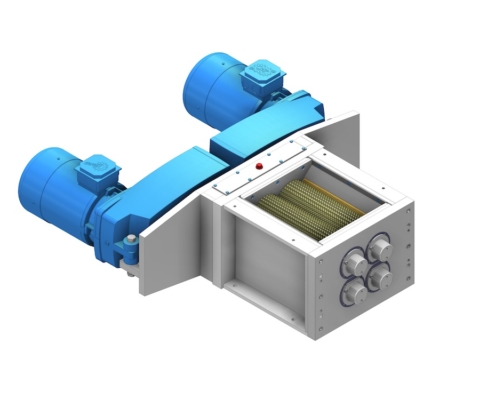

MOCO has developed various cutters for each shredder according to the specific properties of each material. The width of the blades, the tooth shape, the number of teeth per blade and their arrangement on the circumference determine the performance characteristics of each cutter. MOCO not only sets high quality standards for the right cutter. Also important are the stable seat on the shaft and easy, service-friendly replacement. As an international manufacturer of shredding machines and complete systems for industrial applications, MOCO is your ideal partner for a wide range of shredding operations. Why so? MOCO has been developing customised shredders since 1971 with over 4000 shredders in use worldwide.

Did you know?

We test and examine the materials to be crushed for different aspects at our state-of-the-art test centre – because each material behaves differently.